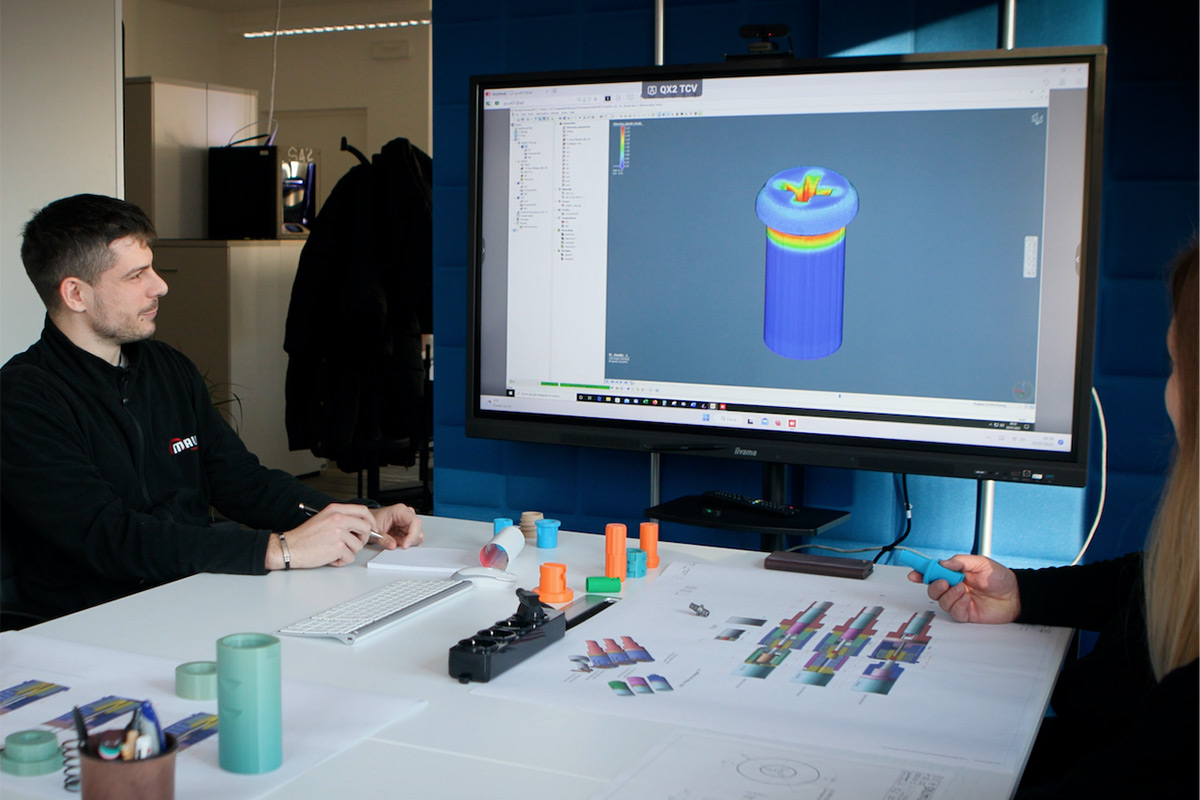

Have you considered Finite Element Analysis (FEA) for your next project?

Finite Element Analysis (FEA) is the simulation of a given physical phenomenon using a numerical technique called the Finite Element Method (FEM). Engineers use FEA software to reduce the number of physical prototypes and experiments, with the aim of optimising components at design phase and developing better products more quickly, with considerable final costs savings.

It is necessary to use the discipline of mathematics to comprehensively understand and quantify any physical phenomena, such as structural behaviour, fluid behaviour, thermal transport, wave propagation, biological cell growth, etc. Most of these processes are described using Partial Differential Equations (PDEs). However, to enable a computer to solve these PDEs, numerical techniques have been developed over the last few decades and, today, one of the most important of which is finite element analysis.

What are the advantages of conducting FEA analysis?

Improved Product Design

One of the most significant advantages of FEA stress analysis is the improvement of the design phase of a product. By identifying critical points of a product and calculating the probability of failure, engineers are able to make design changes to ensure that the product can withstand real-world forces. This can result in a stronger, more durable product with a lower likelihood of failure.

Reduced Development Time and Costs

FEA stress analysis can also help reduce the time and costs associated with developing a new product. By identifying potential issues in the early stages of the design process, engineers can make design modifications before production, mitigating the risk of costly and time-consuming failures. In addition, design engineers will be able to test more design alternatives based on performance, with the added certainty of bringing to market products derived from optimal designs supported by extensive research, testing and data.

Enhanced Safety

FEA stress analysis can further help increase the safety characteristics of a product. Engineers can modify the design by identifying critical points, ensuring the product is less likely to fail and preventing accidents and injuries.

Optimized Performance

During the identification and in-depth testing of a product in relation to its load-bearing points, engineers will be able to make design changes in advance of the production phase in order to ensure its ultimate performance. Products will be more efficient and have a longer lifespan, increasing the level of product reliability and consolidating consumer confidence in the brand.

If you have specific requests or need further assistance with your project, please do not hesitate to contact us.